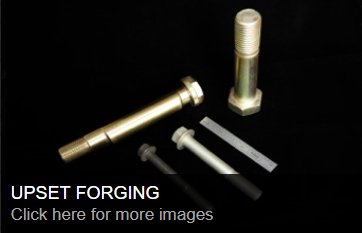

UPSET FORGING

A bar of uniform cross section, usually round, is held between grooved dies, pressure is applied on the end in the direction of the axis of the bar by using a heading tool which spreads the end by metal displacement.

Upset Forging Properties

- Typical size 1/2″-2.5″ diameter stock

- Good dimensional accuracy

- Rapid production rate

- High reliability

- Large material savings

- Reduced machining required

- Controlled grain flow

- High impact characteristics

- Typical machining- Turning/threading/milling

Ask A Question

Fields Marked with * are required